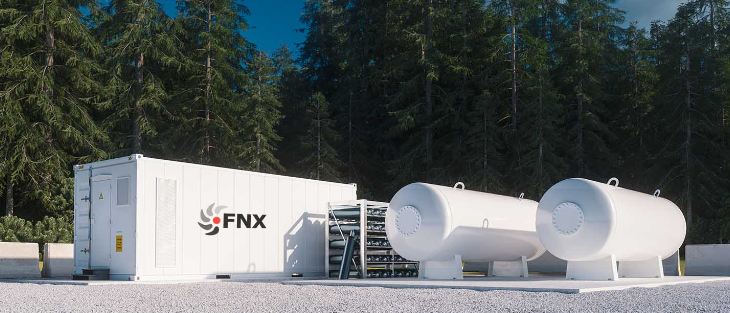

Nitrogen generators continuously produce high-purity nitrogen gas from compressed air. They use a combination of selective permeation membrane and pressure swing absorption (PSA) technologies to separate nitrogen from ambient air.

Nitrogen is used in miscellaneous industries throughout the UK, including food and beverage, electronics, petrochemical and pharmaceutical operations. It can help avoid product spoilage or corrosion in many industrial processes.

Ease of Installation

Nitrogen generators are compact, straightforward to use and can be effortlessly installed in a diverse assortment of commercial environments. These units help industrial operators eliminate the cost of nitrogen tank rental/replacement fees and reduce operating expenses.

These units also make a safer alternative to bulk gas delivery, reducing the risk of leaking tanks that deplete oxygen levels in the workspace. In addition, they eliminate the need for a staff member to handle multiple cylinders.

This allows a facility to focus on its core business while eliminating costs associated with nitrogen tank rentals/replacement and gas supplies.

Before investing in quality nitrogen generators, it is crucial to verify that your facilities electrical, space and ventilation systems can support the system’s operation. Peak’s technical specialists will visit your facility to confirm suitability and to discuss any specific operational environment requirements.

Cost-Effectiveness

Whether you are running a small laboratory or need high flow, high purity nitrogen for your production processes, on-site generators can help you save money on gas supplies. Compared to cylinder or dewar supplies, on-site nitrogen systems are exceptionally cost-effective with short paybacks, in many cases less than twelve months.

In addition, on-site nitrogen systems reduce the need to transport bulk liquid gas or cylinders across site, which cuts down on transportation emissions that increase a business’s carbon footprint. Nitrogen generators also eliminate the risk of leaks or spills from cylinders, which can be dangerous and cause serious injury.

With the supply of carbon dioxide dwindling in New Zealand, many businesses are considering alternative sources for their nitrogen needs. Nitrogen generators are an excellent solution to these shortages because they can produce the gas you need at your location, at your own pace and under your control. They can also help eliminate supply chain hiccups that can be costly to a business and cause downtime.

Reliability

Businesses that rely on nitrogen for their manufacturing processes could save tremendous amounts of money by investing in an onsite nitrogen generator. These devices can produce incredibly pure nitrogen gas on demand, eliminating the need for shipments and ensuring reliability at all times.

Nitrogen is an inert gas that has many industrial applications, including reducing the risk of product spoilage and dissolving oxygen-based organisms. It also ensures that chemical plants and manufacturing facilities are safe from fire and explosion.

For example, in the food industry, nitrogen generators are used to flood food packages with nitrogen to help reduce oxidation and prolong the shelf life of foods and other products. Similarly, high pressure generators are used to reduce the oxygen levels in chemicals and other substances that are susceptible to fire or explosion.

However, the lifespan of these generators varies depending on environmental conditions and how well they are maintained. The generators should be serviced regularly, so they can remain in peak operating condition and function at their best.

Flexibility

Nitrogen generators are highly versatile and adaptable to a wide variety of applications, allowing them to be customized to suit the needs of each facility. PSA nitrogen generators are widely used in food and beverage packaging, electronics manufacturing, chemical industries, medical facilities and wastewater treatment plants to separate high-purity gas from a compressed air stream.

Unlike bottled or bulk liquid nitrogen, on-site generation of nitrogen is more cost-effective and can reduce nitrogen costs by an average of 80%. This can cut operating costs, eliminate repeating gas rental fees and save time on in-house re-supply orders.

Membrane nitrogen generators are also flexible systems and can be configured to meet the demands of small, medium and large flow, medium, high and very high purity nitrogen requirements. They can be equipped with variable cycle saver (VCS) to optimize the adsorption process during low demand and cold temperatures. They also come with a number of features that help to minimize air consumption and energy waste.

Grace Hamilton is an experienced tech journalist with a passion for exploring innovations in cloud computing and media solutions. Her work centers on breaking down technical concepts, offering best practices, and keeping readers informed about the latest trends in secure digital hosting.